For every dough-handling need, there’s a Peerless solution to get the job done with the speed and precision you demand.

Dough Feeding Equipment

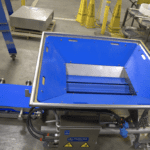

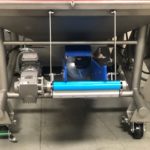

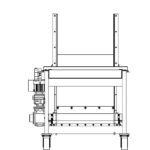

Rotary Dough Feeder

The Peerless Rotary Dough Feeder (RDF) feeds uniform blocks of dough for product processing without changing the dough properties or temperature. Suitable for bread, rolls, buns, bagels and flour tortillas.

Key Features

- Does not change dough properties nor add energy.

- Provides consistent output to maintain desired feed rate for downstream equipment.

- Custom-designed hoppers designed for your exact applications.

- High feed rates with multiple cutter sizes available.

- Open design for ease of sanitation and routine maintenance.

- Quiet operation and portable design for confined areas.

- Eliminates the need for trough hoists, trough handling and large hoppers.

- Handles from 500 lbs (226 kgs) to 22,000 lbs (9,980 kgs) of dough per hour.

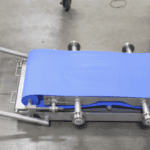

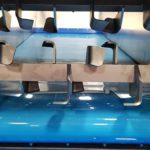

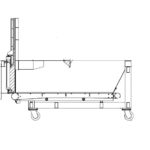

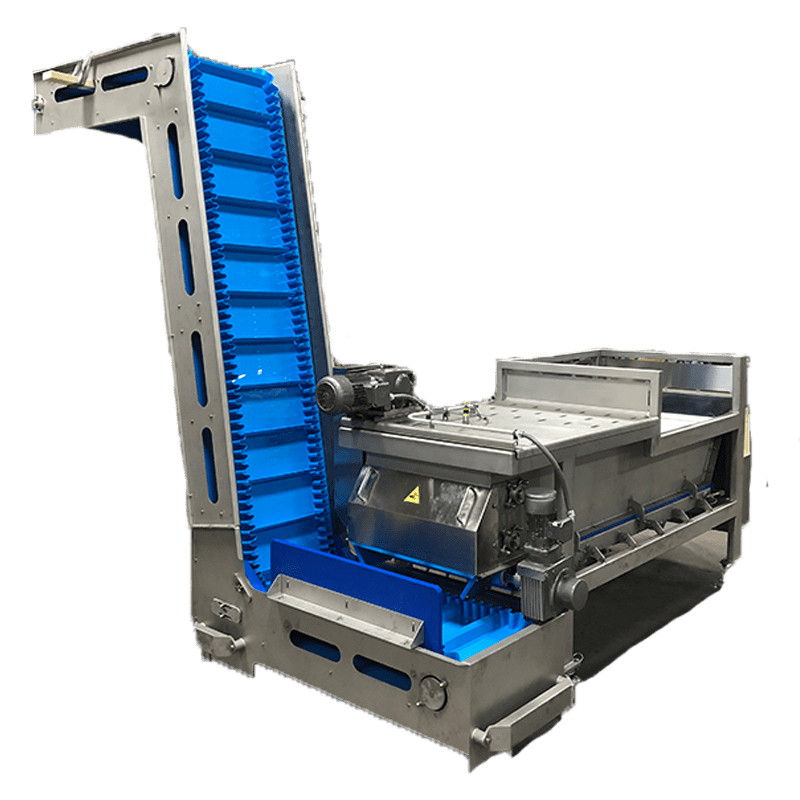

Tine Dough Feeder

The Peerless Tine Dough Feeder uses rotating tines to break up clumps of dough and provide a uniform feed to forming equipment. Suitable for products with product characteristics similar to rotary biscuit doughs or corn masa.

Key Features

- Provides consistent output to maintain desired feed rate for downstream equipment.

- Urethane coated polyester or Intralox conveyor belt for product transfer.

- Handles from 500 lbs to 12,000 lbs of dough per hour.

- Open design for ease of sanitation and maintenance.

- Motors, gearboxes, sprockets and bearings are designed for wash-down service.

Options

- Flighted discharge conveyor.

- Horizontal conveyors to feed dough to forming equipment.

- Programming and automation to accept product from multiple mixers.

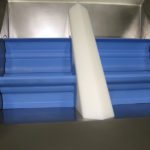

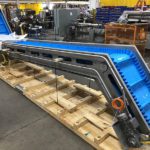

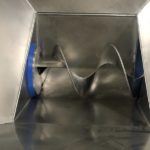

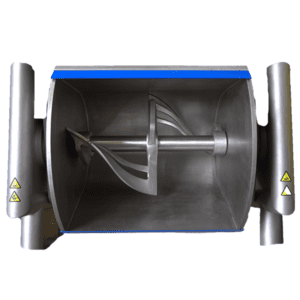

Spiral Dough Feeder

The Peerless Spiral Flow Dough Feeder is designed to feed a continuous supply of dough to the hopper of a dough divider or forming equipment without changing the dough condition or increasing its temperature. Handles a wide variety of doughs including bread, roll, frozen dough, as well as biscuit, cracker and snack doughs.

Key Features

- Unique spiral auger gently moves dough without changing the dough characteristics.

- Hopper capacities from 500 pounds to 3000 pounds of dough with output rates of 500 to 12,000 pounds per hour.

- Gentle on product causing minimal to no energy addition to dough.

- Power requirement substantially less than conventional dough feeding systems.

- Operator friendly/minimal training requirements.

Options

- Power traverse for use with multiple mixers.

- Vertical discharge conveyors and dough feed conveyors to automatically feed one or more processing lines.

- Integrated with mixer control system.

- Special hopper configurations.

- Blue UHMW lined, removable hopper to reduce dough sticking.

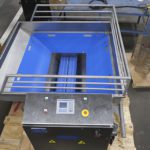

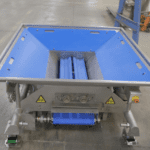

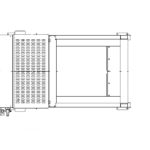

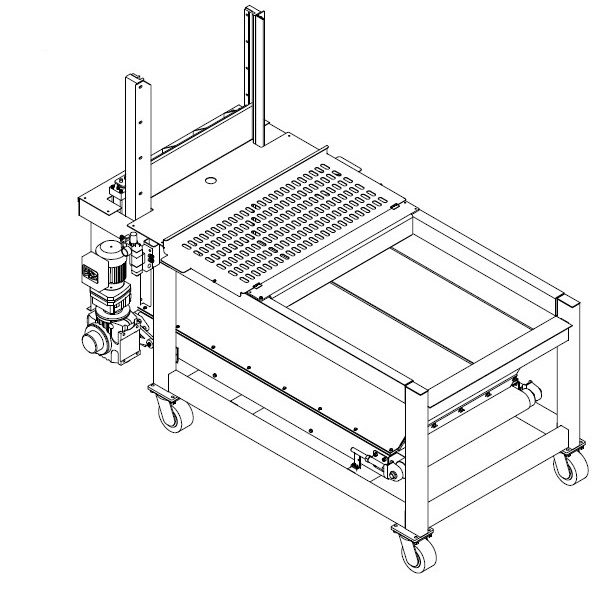

Guillotine Dough Feeder

The Peerless Guillotine Dough Feeder automatically and delicately feeds uniform blocks of dough to the dough divider or forming equipment without changing the product characteristics or temperature.

Key Features

- Systems maintain a constant level of dough in the divider or forming machine hopper for improved scaling and forming accuracy

- Feeds from 500 lbs to 12,000 lbs of dough per hour

- Pneumatic controlled portioning device

- Open design for ease of sanitation and routine maintenance

Options

- Various hopper designs, capacities and materials of construction available

- Polyethylene lined hopper to reduce dough sticking

- Programming and automation to accept product from multiple mixers

“The mixer, in conjunction with the RDF (rotary dough feeder) and conveyor, have made our production process much more user-friendly. Our employees can produce significantly more product with greater efficiency, all while reducing physical stress.”

– OCHO Candy