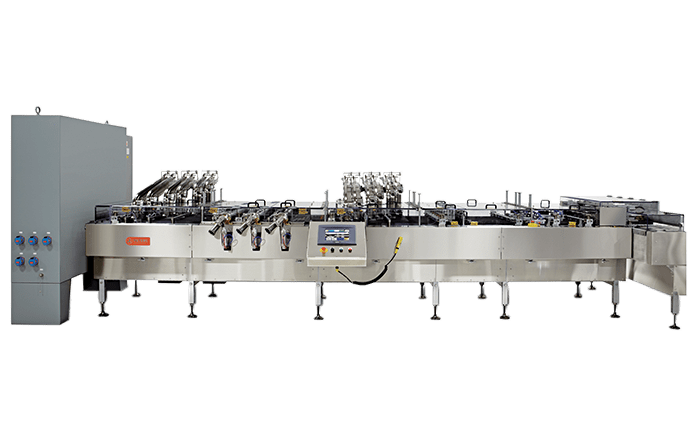

Peters, a brand of Peerless Food Equipment, introduced the first high-speed sandwiching machine to the baking world nearly a century ago. Since then, these machines have become the industry standard for reliable, efficient, and profitable production. The Peters Sandwiching Machines incorporate everything our customers demand — low maintenance and sanitation downtime, easy changeovers, consistent product quality and high production rates. The attention to detail has earned Peters the reputation as the world’s leading producer of sandwiching equipment for bakery manufacturers.

Peters Sandwiching Machine/Biscuit Creamer

Performance and Versatility at Your Fingertips

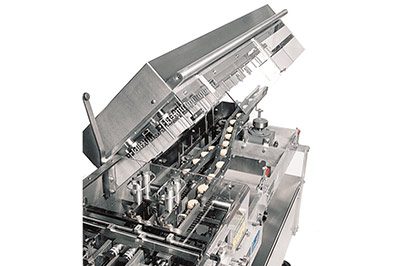

PT2

1,600 sandwiches per minute

Key Features

- Sanitary design with stainless steel and aluminum construction — no painted surfaces in the product zone

- Speeds up to 1,600 sandwiches per minute

- Shapes: can handle a wide variety of base cake shapes, including round, square, rectangle, or specialty shapes

- Standard product size range of 38 mm – 60 mm

- “Mini” sandwiches – typically 25 mm – 38 mm diameter – can be produced with optional changes to the standard machine (maximum machine speed may be increased)

- Can accommodate larger products up to 100 mm in length depending upon specific application (maximum machine speed may be reduced with optional changes)

- Wide variety of fillings can be used, including creams, peanut butter, cheese and jelly

- Product discharged in multiple configurations

- Portable Cream Hopper for accurate and consistent cream delivery

Custom Options

- An independent cream pump per lane, providing individual control of cream deposits and highly accurate deposit weights

- Available in 1 thru 6 lane machines

- Speeds up to 800 sandwiches per minute per lane

- Equipment can be manually loaded or automatically fed, and can be configured to suit virtually any bakery layout

- Servo Driven system for easy maintenance

- Deposit options for multiple products including two crème flavors on one deposit and double deposits for single or multiple cream flavors

- Wide variety of fillings can be used, including creams, peanut butter, cheese and jelly

- Sanitary design with stainless steel and aluminum construction — no painted surfaces are in the product zone

- Available with downstream connection to Row Combiner, Multiplier, Slug Loader, and Tray Loader

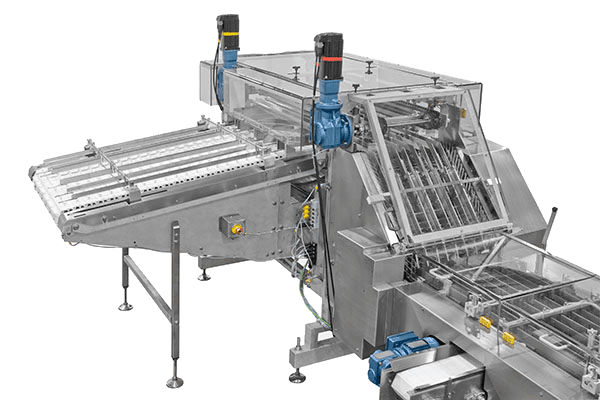

PT4

3,200 sandwiches per minute

Key Features

- Sanitary design with stainless steel and aluminum construction — no painted surfaces in the product zone

- Speeds up to 3,200 sandwiches per minute

- Shapes: can handle a wide variety of base cake shapes, including round, square, rectangle, or specialty shapes

- Standard product size range of 38 mm – 60 mm

- “Mini” sandwiches – typically 25 mm – 38 mm diameter – can be produced with optional changes to the standard machine (maximum machine speed may be increased)

- Can accommodate larger products up to 100 mm in length depending upon specific application (maximum machine speed may be reduced with optional changes)

- Wide variety of fillings can be used, including creams, peanut butter, cheese and jelly

- Product discharged in multiple configurations

- Portable Cream Hopper accurate and consistent cream delivery

Custom Options

- An independent cream pump per lane, providing individual control of cream deposits and highly accurate deposit weights

- Electrical interface to support automatic, upstream biscuit feeding

- Servo Driven system for easy maintenance

- Deposit options for multiple products including standard deposit, two crème flavors or deposit and double deposit for single or multiple cream flavors

- Available with downstream connection to Row Combiner, Multiplier, Slug Loader and Tray Loader.

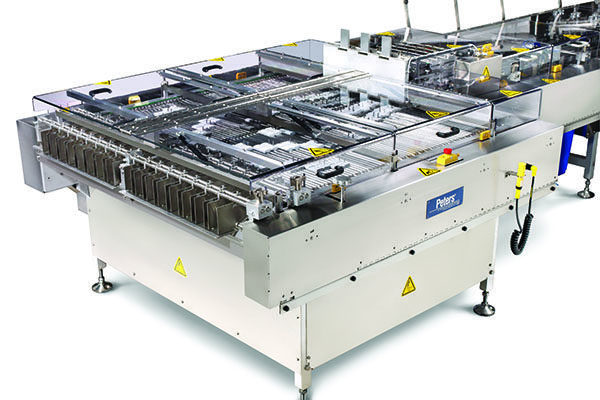

PT6

4,800 sandwiches per minute

Key Features

- Sanitary design with stainless steel and aluminum construction — no painted surfaces in the product zone

- Speeds up to 4,800 sandwiches per minute

- Shapes: can handle a wide variety of base cake shapes, including round, square, rectangle, or specialty shapes

- Standard product size range of 38 mm – 60 mm

- “Mini” sandwiches – typically 25 mm – 38 mm diameter – can be produced with optional changes to the standard machine (maximum machine speed may be increased)

- Can accommodate larger products up to 100 mm in length depending upon specific application (maximum machine speed may be reduced with optional changes)

- Wide variety of fillings can be used, including creams, peanut butter, cheese and jelly

- Product discharged in multiple configurations

- Portable Cream Hopper that provides accurate and consistent cream delivery

Custom Options

- An independent cream pump per lane, providing individual control of cream deposits and highly accurate deposit weights

- Electrical interface to support automatic, upstream biscuit feeding

- Servo Driven system for easy maintenance

- Deposit options for multiple products including standard deposit, two crème flavors on 1 deposit and double deposit for single or multiple cream flavors

- Available with downstream connection to Multiplier

“We appreciate all the efforts Peerless has put in for the successful installation of the Oreo line. This was a major investment project for us, and we chose premium suppliers of equipment such as Peerless to give us the best results.”

– Parsons Nutritionals