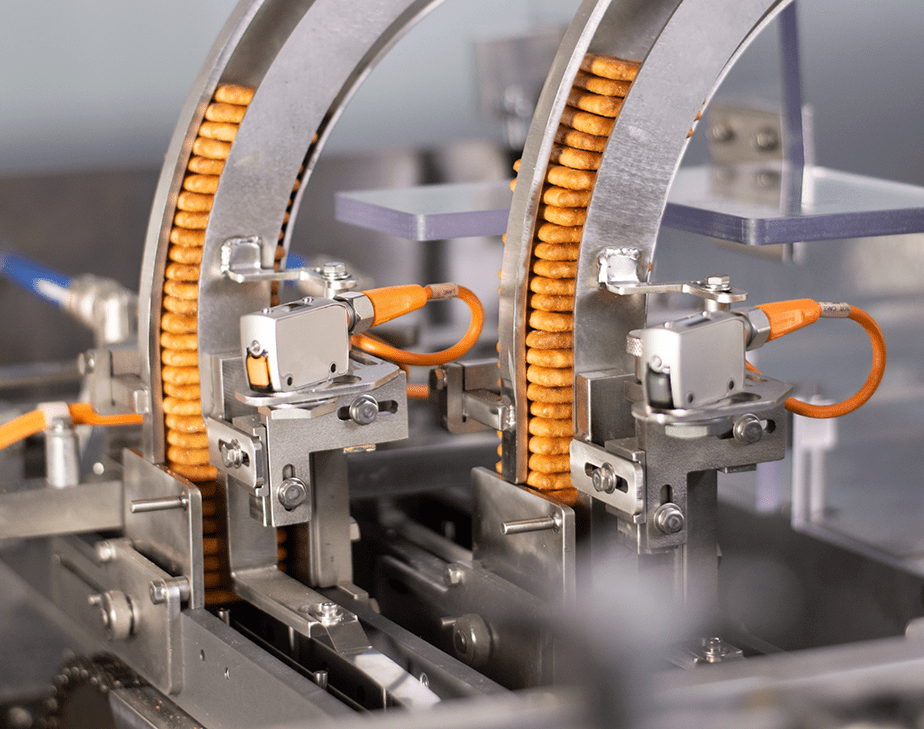

With Peerless Food Equipment, you’ll find our sanitary designs are more than just words. Our team has the latest certifications and training, and we comply with all ANSI/ASB/Z50.2-2015 Sanitation Standards for the Design of Bakery Equipment criteria.

Sanitary equipment design is essential to ensuring food safety, high quality and efficiency in your production lines. The more sanitary the design, the less sanitation costs you face. That’s a win for all.