The Peerless Enclosed Frame Mixer delivers high-capacity mixing performance, helping meet your demand. The unibody design provides strength and stability, regardless of the load size or dough type. The Peerless single-end drive system provides substantial advantages over competitive mixers, resulting in stronger drives, shafts and bearings. Greater bowl tilt flexibility and a cleaner, more compact design.

Traditional Enclosed Frame Mixer

A high-capacity mixer known for its durability, reliable performance and problem-free operations.

Traditional Enclosed Frame Mixers - Agitator Options

Traditional Enclosed Frame Triple Roller Bar Mixer

Key Features

- ANSI/ASB/Z50.2/BISSC & CE Certified.

- Best for breads, flour tortillas, pizzas, bagels, doughnuts, croissants, buns, rolls and English muffins.

- Created from robust, food-grade, 304 Stainless Steel. The roller bars and shaft are designed and fabricated for food contact surfaces (Ra 1.6 µm (Ra 63 µin), meeting the sanitation standards your product requires.

- With consistent kneading action, the roller bars deliver maximum energy transfer creating exceptional dough development.

- Heavy-duty “unibody” frame design for robust performance.

- Enclosed frame mixers built with a straight grain finish.

- High Efficiency, IEEE premium duty, waterproof motor.

- Bowl seal, made with FDA-approved material, minimizes leaking and preserves product safety.

- Sanitary drip shield provides a spill barrier over motor for easy cleanup.

- Minimal maintenance trunnion bearings for the ultimate in sanitation and up-time.

- Gates Poly Chain GT Carbon drive belt reinforced drive belt.

- Heavy-duty stainless steel “Z”-type jacket for superior strength when cooling/warming bowl sheet.

- Custom Mixer Cycle System (CMCS) allows for the creation and storage of mix cycles.

- Hydraulic bowl tilt 120° forward.

- NEMA 12/dust-tight, painted remote starter enclosure.

Custom Options

Frame:

- Manual or automatic trough hooks

- Trough in-place safety sensors

- Dump side stainless steel bowl guard equipped with two interlocked hinged doors

Bowl:

- Direct expansion refrigeration jacket and fittings (please specify refrigerant)

- Bowl drain valve

- Cold Bar System (with refrigerated breaker bar & bowl end cooling)

- Cold Bar Plus Refrigerated Agitator System

Tilt:

- Forward tilt up to 140° forward (hydraulic actuator)

- Two-Way-Tilt (TWT) up to 140° Forward/Reverse

Canopy:

- Anti-drip adapters

- Interlocked ingredient door for minor ingredients

- Rear sponge door

- BFM fitting(s) for product gate(s)

- Metal Detectable bowl side seals

Electrical:

- Auxiliary control panel with basic mixer controls

- NEMA 4X (IP66 rated) stainless steel starter enclosure (in lieu of painted)

- Sanitation cover for operator panel

- Maintenance and Engineering Convenience Package, which includes enclosure lighting and a grace port with externally mounted utility receptacle and “closed door” programming access.

- Increased screen size for Allen Bradley Panel View +7

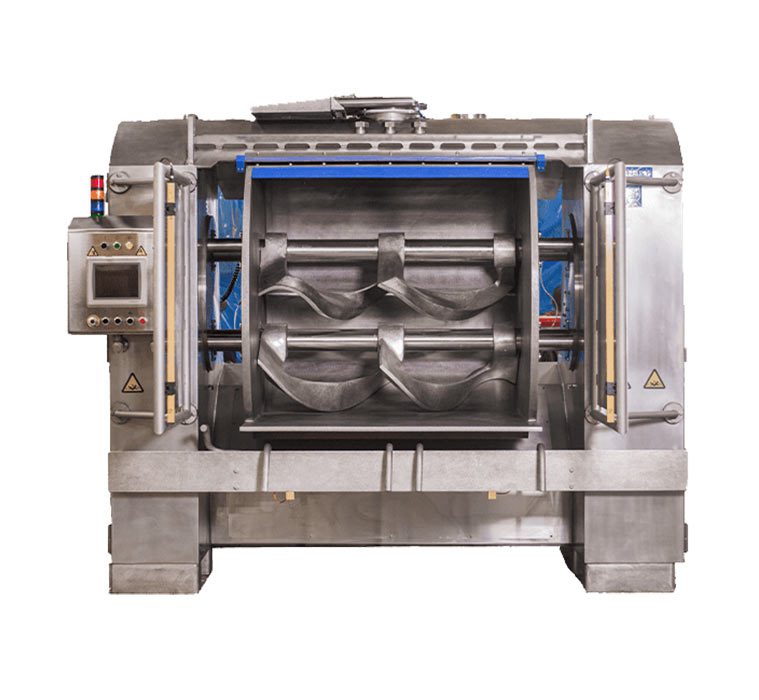

Traditional Enclosed Frame Double Sigma Arm Mixer

Key Features

- ANSI/ASB/Z50.2/BISSC & CE Certified.

- Ideal for wire-cut cookie dough, cake, doughnuts, muffins, pretzels, granola, energy bars, scones, cream filling, Italian Christmas breads and fig jam.

- The agitators work in a thorough, uniform motion supplying a center of the bowl mix while creating high shear and a back and forth product movement.

- Created from robust, food-grade, 304 Stainless Steel, the agitator and shaft are designed and fabricated for food contact surfaces (Ra 1.6 µm (Ra 63 µin), meeting the sanitation standards your product requires.

- Heavy-duty “unibody” frame design for robust performance.

- Enclosed frame mixers built with a straight grain finish.

- High Efficiency, IEEE premium duty, waterproof motor.

- Bowl seal, made with FDA-approved material, minimizes leaking and preserves product safety.

- Sanitary drip shield provides a spill barrier over motor for easy cleanup.

- Minimal maintenance trunnion bearings for the ultimate in sanitation and up-time.

- Gates Poly Chain GT Carbon drive belt reinforced drive belt.

- Heavy-duty stainless steel “Z”-type jacket for superior strength when cooling/warming bowl sheet.

- Custom Mixer Cycle System (CMCS) allows for the creation and storage of mix cycles.

- Hydraulic bowl tilt 120° forward.

- NEMA 12/dust-tight, painted remote starter enclosure.

Custom Options

Frame:

- Manual or automatic trough hooks

- Trough in-place safety sensors

- Dump side stainless steel bowl guard equipped with two interlocked hinged doors

Bowl:

- Direct expansion refrigeration jacket and fittings (please specify refrigerant)

- Bowl drain valve

- Cold Bar System (with refrigerated breaker bar & bowl end cooling)

- Cold Bar Plus Refrigerated Agitator System

Tilt:

- Forward tilt up to 140° forward (hydraulic actuator)

- Two-Way-Tilt (TWT) up to 140° Forward/Reverse

Canopy:

- Anti-drip adapters

- Interlocked ingredient door for minor ingredients

- Rear sponge door

- BFM fitting(s) for product gate(s)

- Metal Detectable bowl side seals

Electrical:

- Auxiliary control panel with basic mixer controls

- NEMA 4X (IP66 rated) stainless steel starter enclosure (in lieu of painted)

- Sanitation cover for operator panel

- Maintenance and Engineering Convenience Package, which includes enclosure lighting and a grace port with externally mounted utility receptacle and “closed door” programming access.

- Increased screen size for Allen Bradley Panel View +7

Traditional Enclosed Frame Single Sigma Arm Mixer

Key Features

- ANSI/ASB/Z50.2/BISSC & CE Certified.

- Ideal for cookies (moulded, laminated and sheeted), crackers, biscuits, corn tortillas, energy bars, pet food and cream filling.

- Double-sweep design works dough in a back-and-forth, up-and-down motion across the bowl. This allows for low-shear incorporation of minor ingredients like chocolate chips, fruits and nuts.

- Created from robust, food-grade 304 Stainless Steel, the agitators and shaft are rated for food contact surfaces (Ra 1.6 µm (Ra 63 µin), meeting the sanitation standards your product requires.

- Heavy-duty “unibody” frame design for robust performance.

- Enclosed frame mixers built with a straight grain finish.

- High Efficiency, IEEE premium duty, waterproof motor.

- Bowl seal, made with FDA-approved material, minimizes leaking and preserves product safety.

- Sanitary drip shield provides a spill barrier over motor for easy cleanup.

- Minimal maintenance trunnion bearings for the ultimate in sanitation and up-time.

- Gates Poly Chain GT Carbon drive belt reinforced drive belt.

- Heavy-duty stainless steel “Z”-type jacket for superior strength when cooling/warming bowl sheet.

- Custom Mixer Cycle System (CMCS) allows for the creation and storage of mix cycles.

- Hydraulic bowl tilt 120° forward.

- NEMA 12/dust-tight, painted remote starter enclosure.

Custom Options

Frame:

- Manual or automatic trough hooks

- Trough in-place safety sensors

- Dump side stainless steel bowl guard equipped with two interlocked hinged doors

Bowl:

- Direct expansion refrigeration jacket and fittings (please specify refrigerant)

- Bowl drain valve

- Cold Bar System (with refrigerated breaker bar & bowl end cooling)

- Cold Bar Plus Refrigerated Agitator System

Tilt:

- Forward tilt up to 140° forward (hydraulic actuator)

- Two-Way-Tilt (TWT) up to 140° Forward/Reverse

Canopy:

- Anti-drip adapters

- Interlocked ingredient door for minor ingredients

- Rear sponge door

- BFM fitting(s) for product gate(s)

- Metal Detectable bowl side seals

Electrical:

- Auxiliary control panel with basic mixer controls

- NEMA 4X (IP66 rated) stainless steel starter enclosure (in lieu of painted)

- Sanitation cover for operator panel

- Maintenance and Engineering Convenience Package, which includes enclosure lighting and a grace port with externally mounted utility receptacle and “closed door” programming access.

- Increased screen size for Allen Bradley Panel View +7

Traditional Enclosed Frame High Shear Mixer

Key Features

- ANSI/ASB/Z50.2/BISSC & CE Certified.

- Ideal for pasta dough, taffy, creams and brownie batter.

- Engineered to produce wet and dissolve sticky powder (gums, thickeners, stabilizers) or other similar tricky tasks, this configuration offers benefits not found in other setups.

- Heavy-duty “unibody” frame design for robust performance.

- Enclosed frame mixers built with a straight grain finish.

- High Efficiency, IEEE premium duty, waterproof motor.

- Bowl seal, made with FDA-approved material, minimizes leaking and preserves product safety.

- Sanitary drip shield provides a spill barrier over motor for easy cleanup.

- Minimal maintenance trunnion bearings for the ultimate in sanitation and up-time.

- Gates Poly Chain GT Carbon drive belt reinforced drive belt.

- Heavy-duty stainless steel “Z”-type jacket for superior strength when cooling/warming bowl sheet.

- Custom Mixer Cycle System (CMCS) allows for the creation and storage of mix cycles.

- Hydraulic bowl tilt 120° forward.

- NEMA 12/dust-tight, painted remote starter enclosure.

Custom Options

Frame:

- Manual or automatic trough hooks

- Trough in-place safety sensors

- Dump side stainless steel bowl guard equipped with two interlocked hinged doors

Bowl:

- Direct expansion refrigeration jacket and fittings (please specify refrigerant)

- Bowl drain valve

- Cold Bar System (with refrigerated breaker bar & bowl end cooling)

- Cold Bar Plus Refrigerated Agitator System

Tilt:

- Forward tilt up to 140° forward (hydraulic actuator)

- Two-Way-Tilt (TWT) up to 140° Forward/Reverse

Canopy:

- Anti-drip adapters

- Interlocked ingredient door for minor ingredients

- Rear sponge door

- BFM fitting(s) for product gate(s)

- Metal Detectable bowl side seals

Electrical:

- Auxiliary control panel with basic mixer controls

- NEMA 4X (IP66 rated) stainless steel starter enclosure (in lieu of painted)

- Sanitation cover for operator panel

- Maintenance and Engineering Convenience Package, which includes enclosure lighting and a grace port with externally mounted utility receptacle and “closed door” programming access.

- Increased screen size for Allen Bradley Panel View +7

“We could not be happier with this mixer. It’s been a godsend on that line and has helped us out tremendously on our products. Any of the issues we had before with the old mixers, they’ve gone away with this one and we could not be happier.”

– MaMa Rosa’s refrigerated pizza